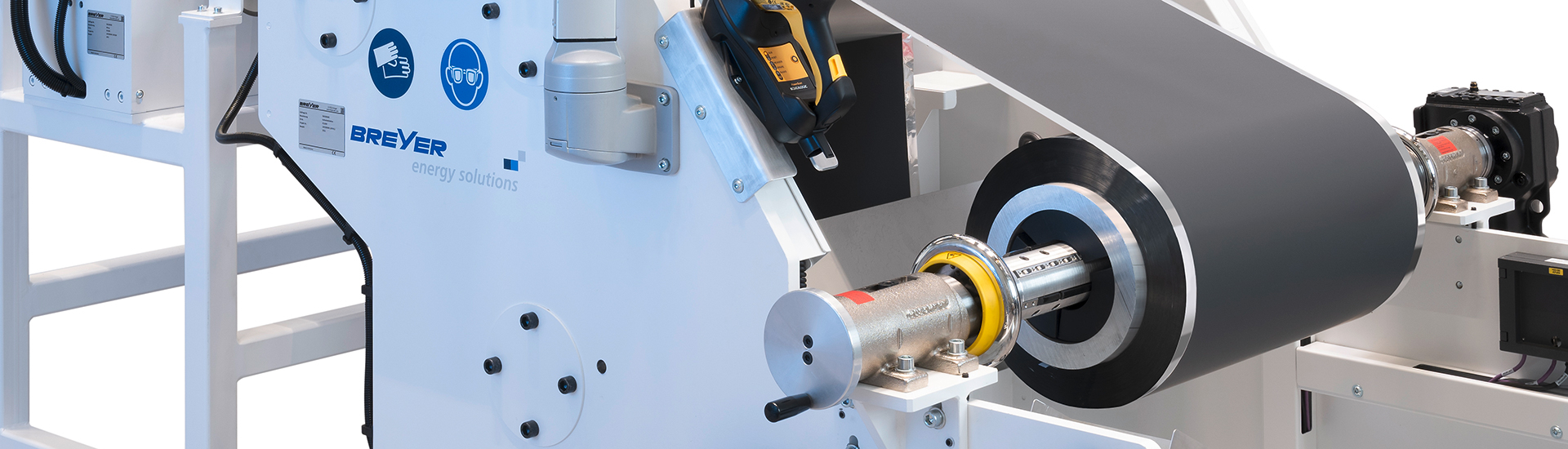

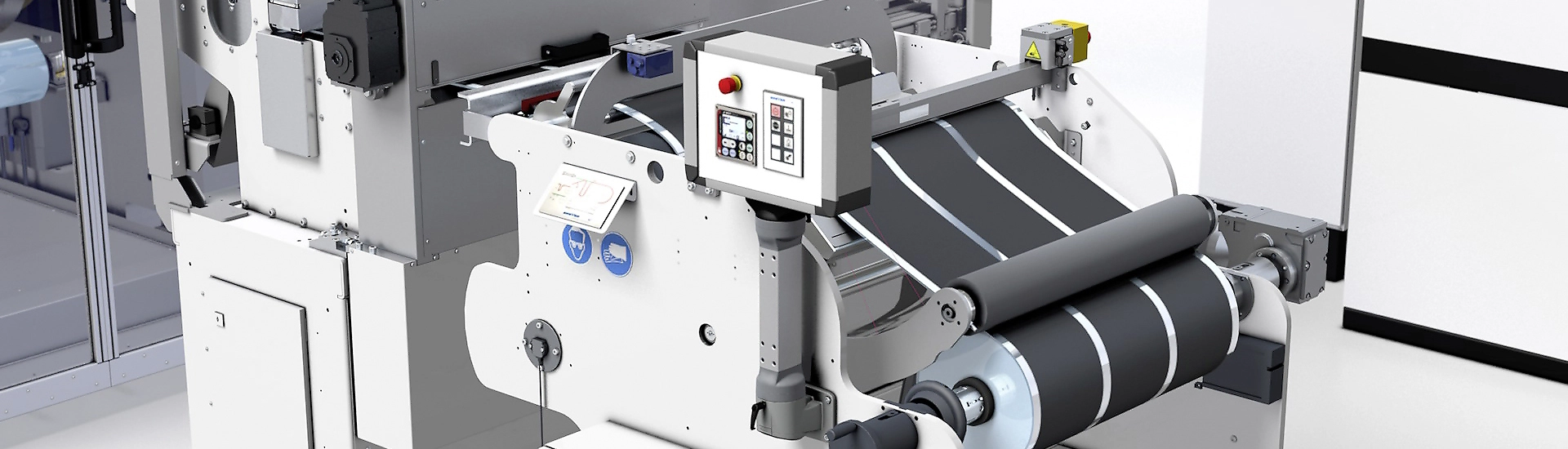

BREYER IONPress

Kalander-Technologie

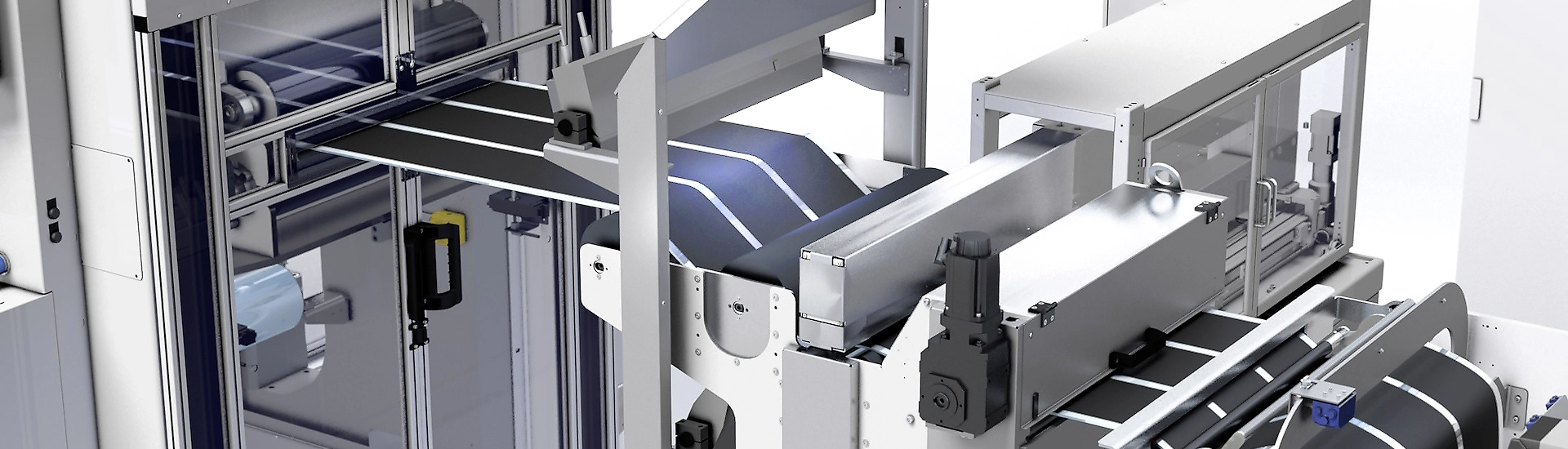

Herstellung von anspruchsvollen Elektrodenfolien für Lithium-Ionen Batterien

Die neue Generation der BREYER IONPress Kalander stellt einen Meilenstein in der Verbesserung der Lithium-Ionen-Elektrodenfolien-Herstellung dar.

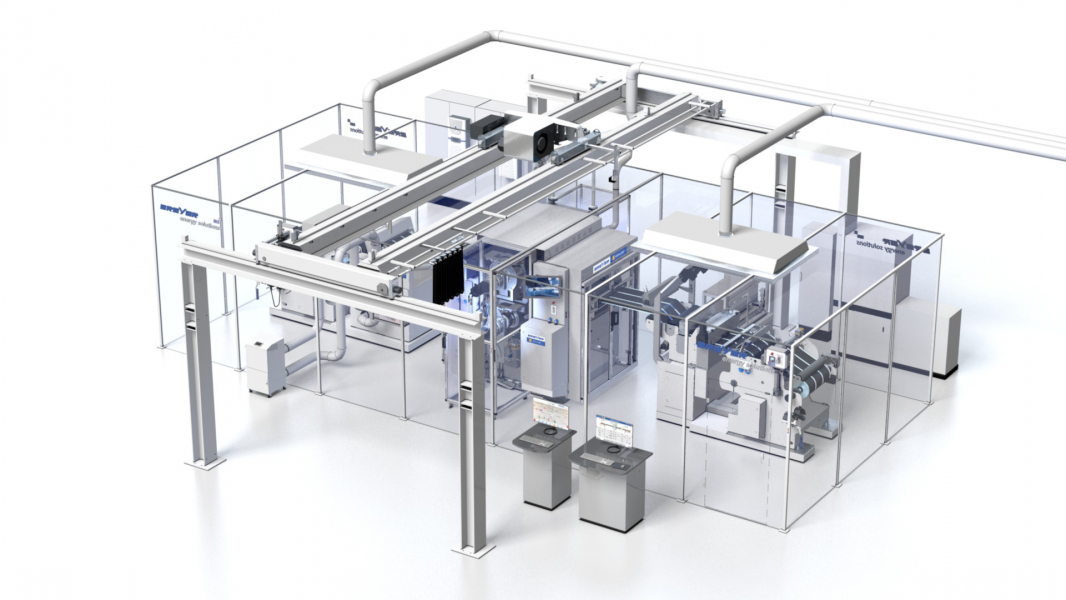

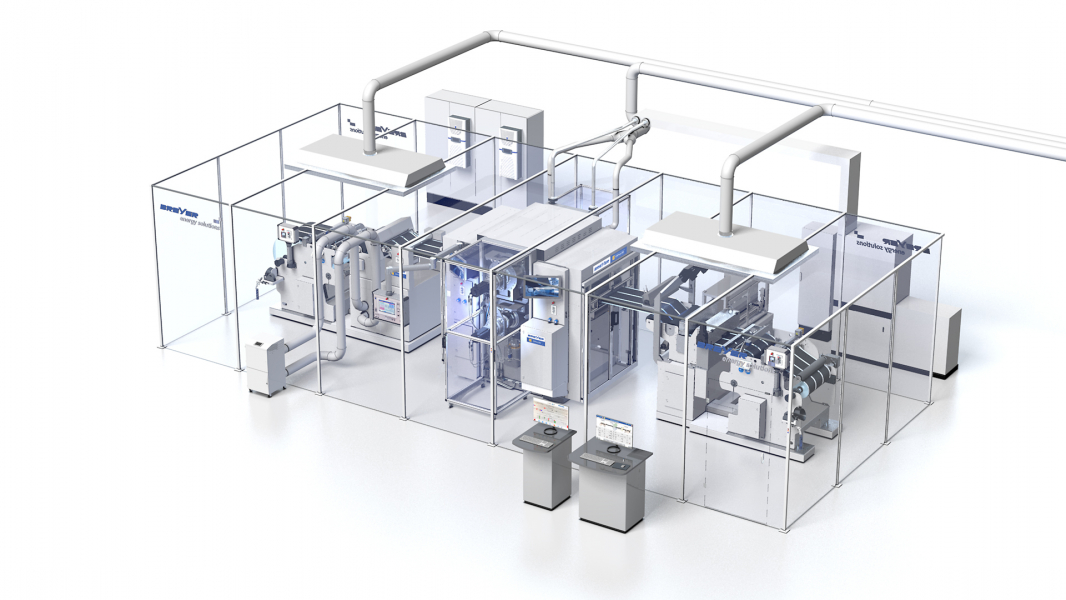

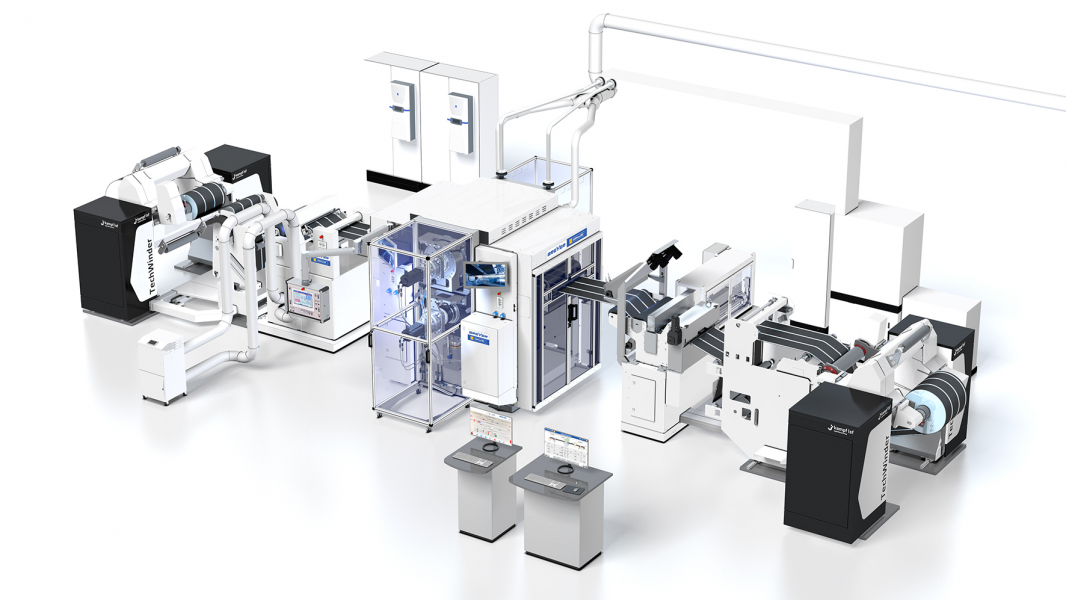

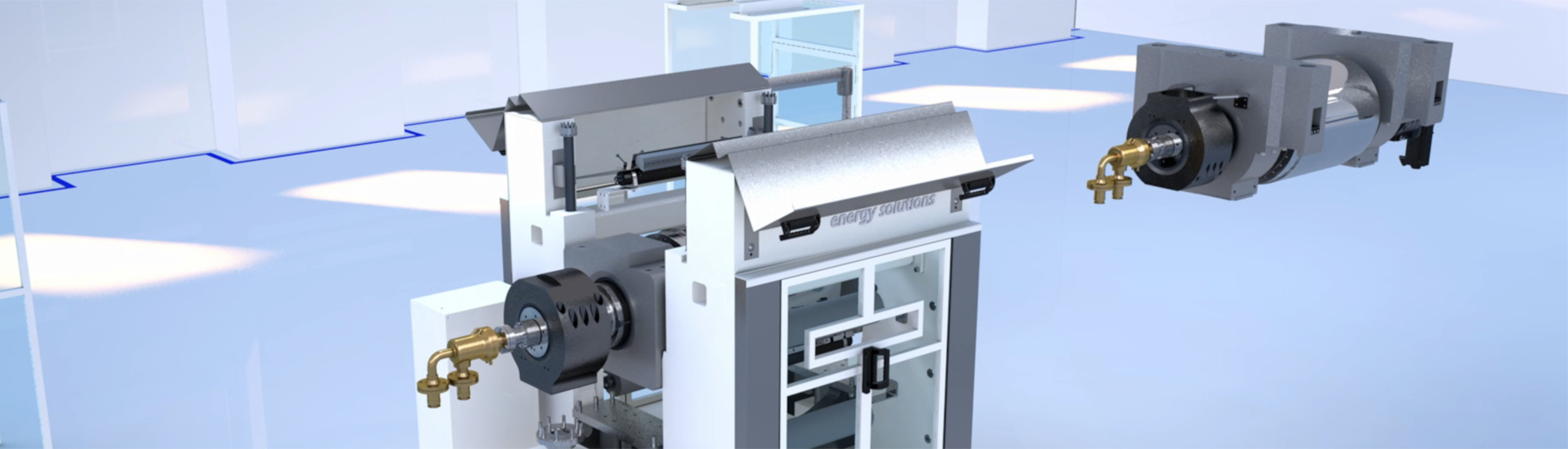

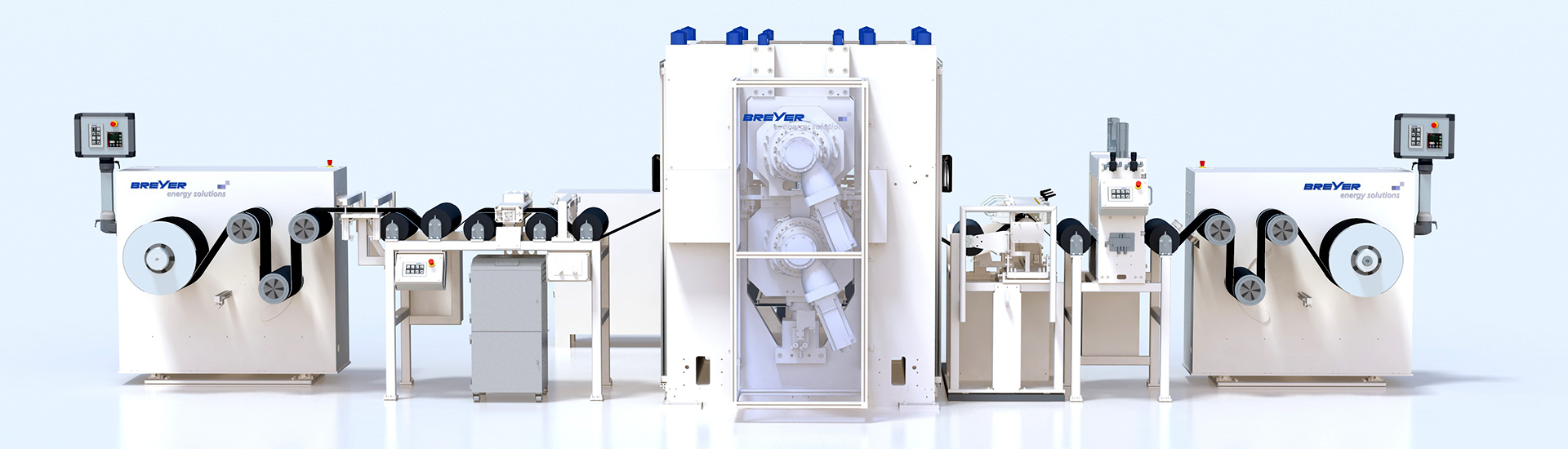

Kalandersystem zur Herstellung von Elektrodenfolien für Lithium-Ionen Batterien

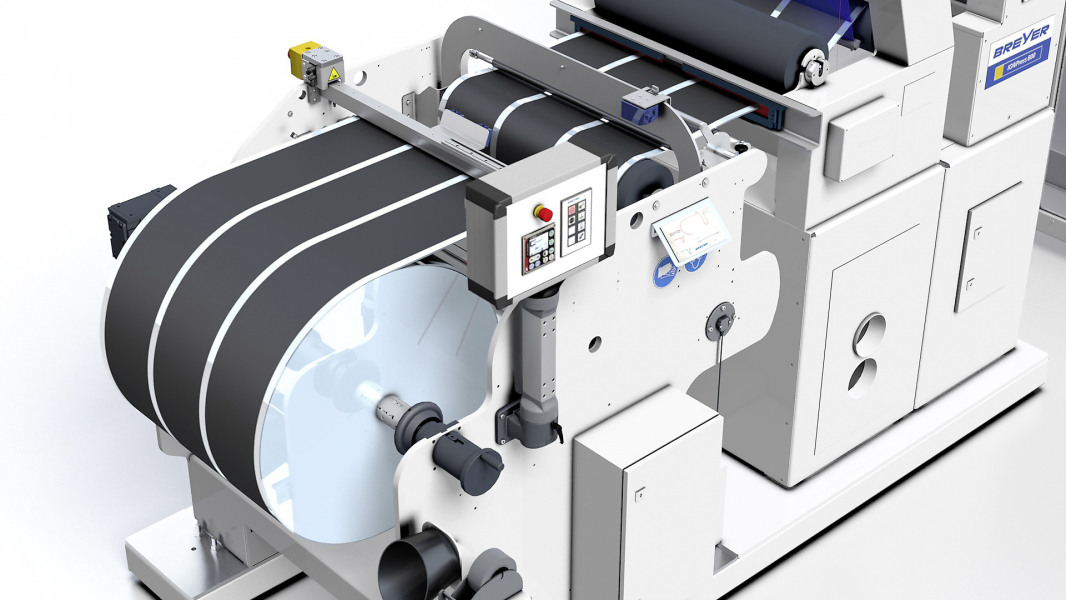

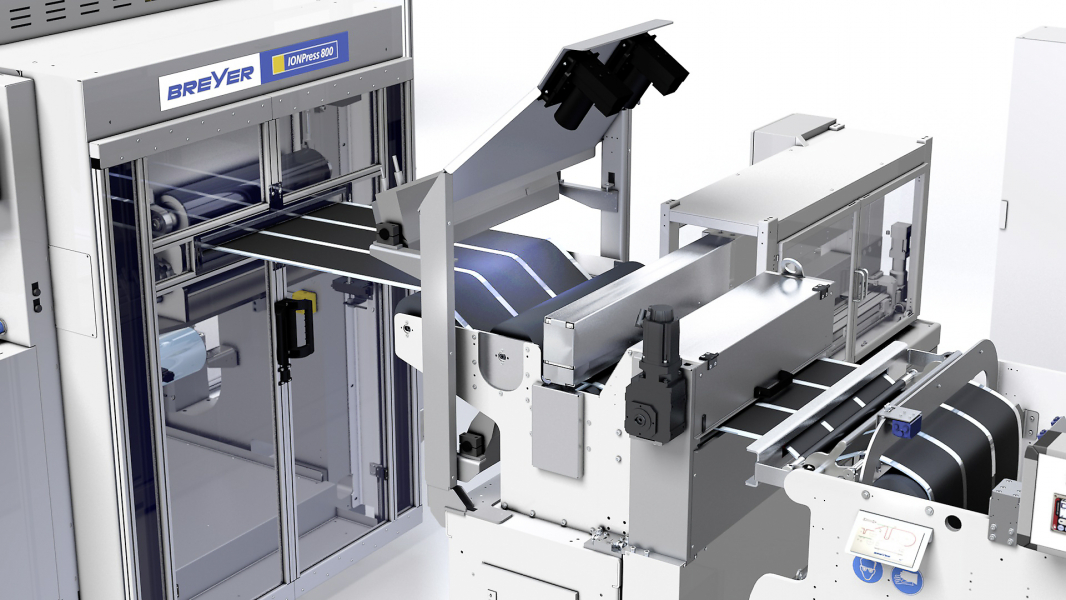

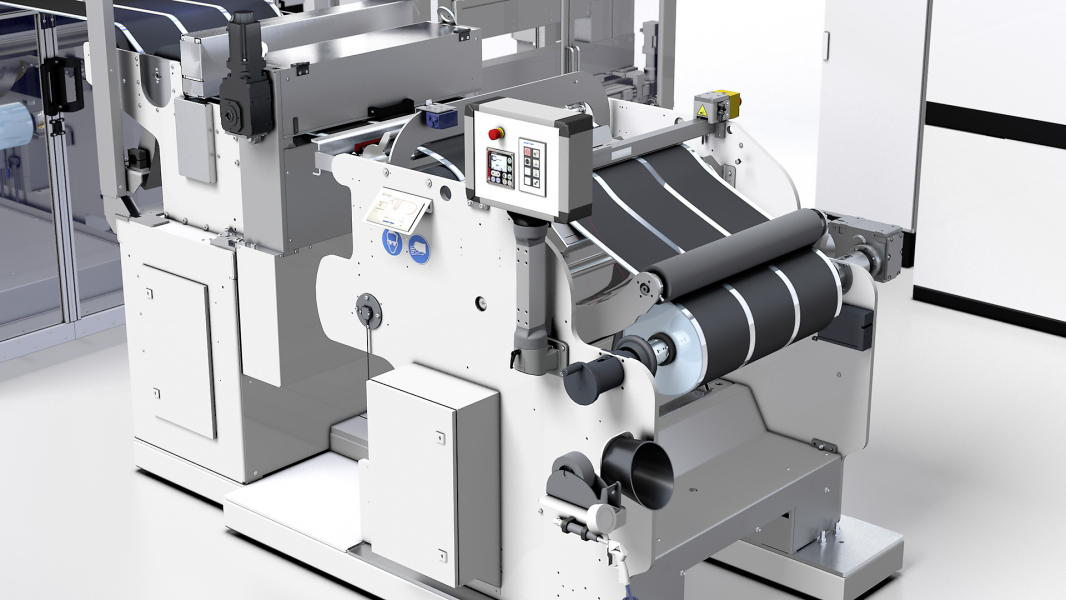

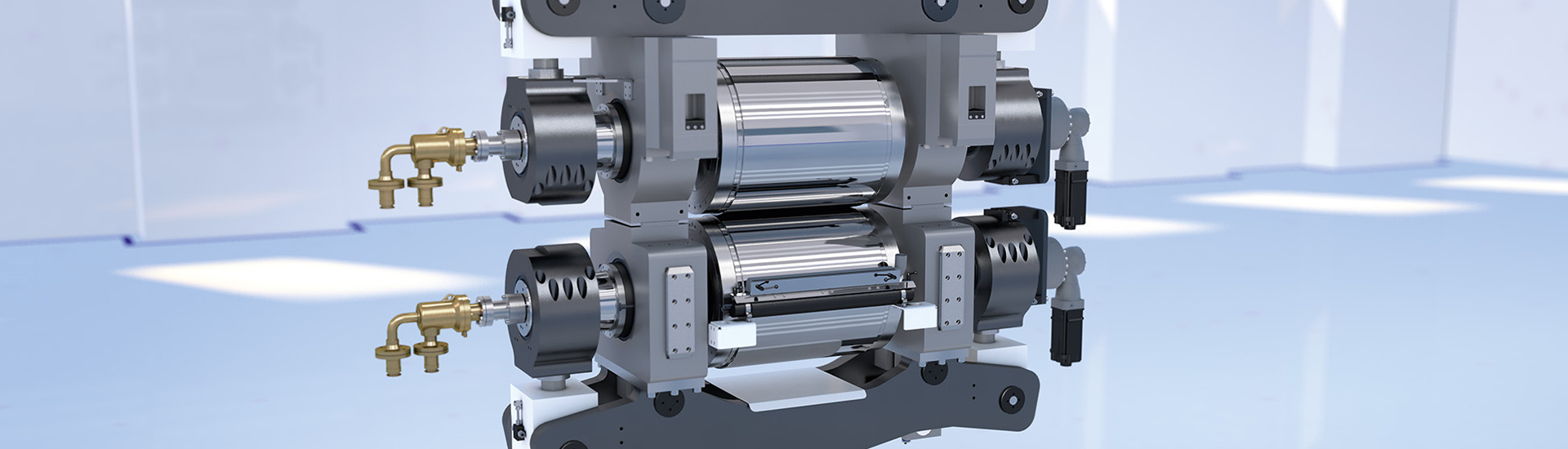

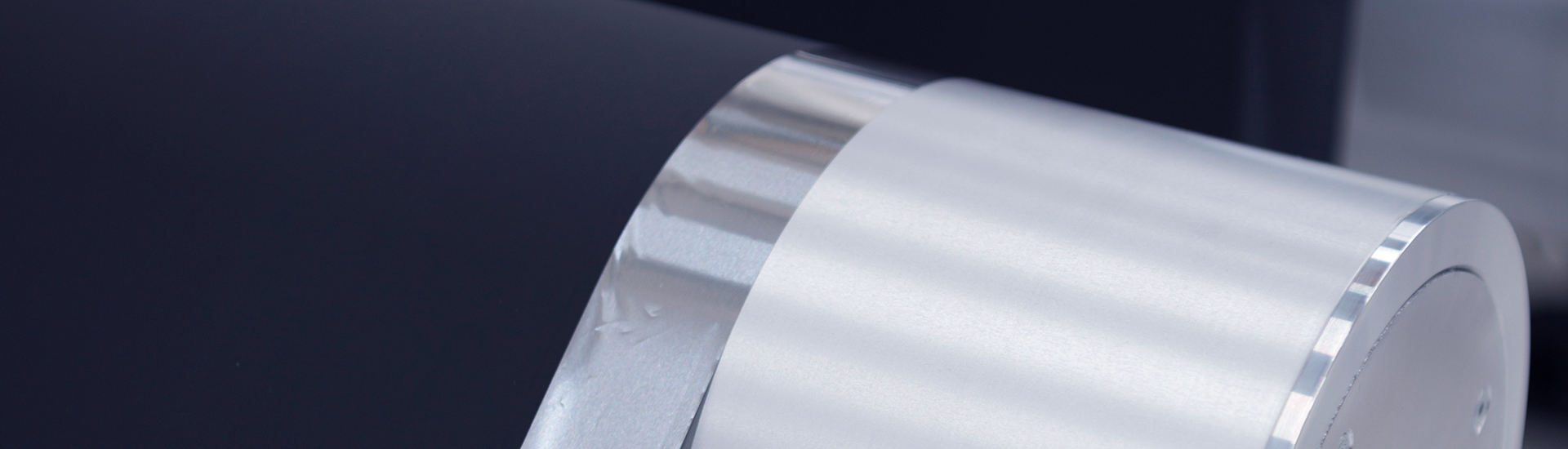

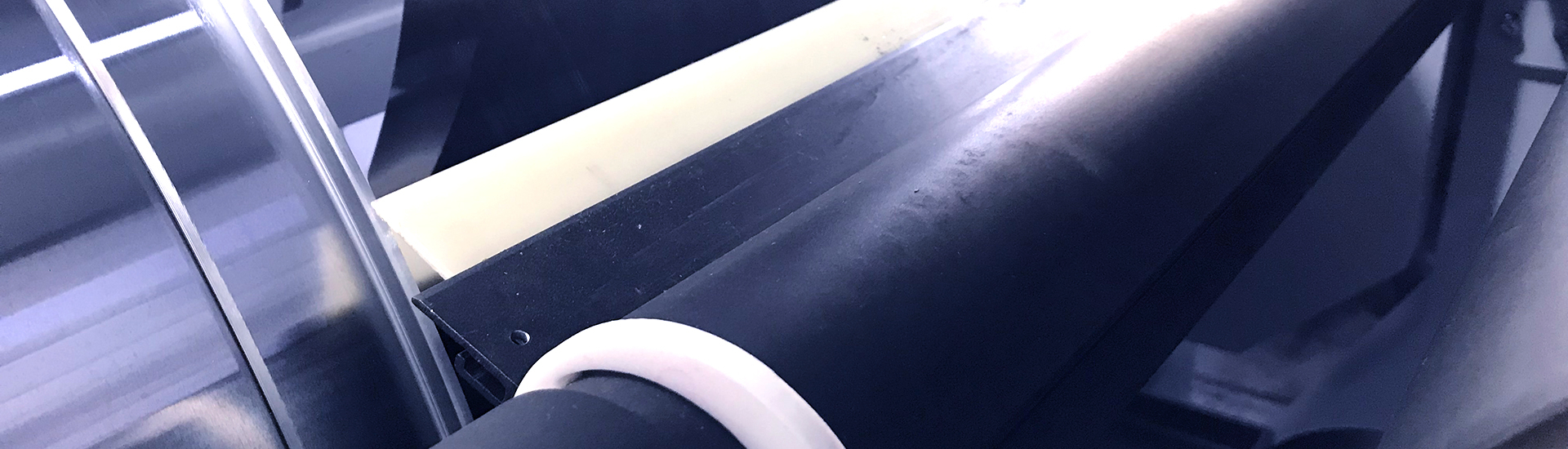

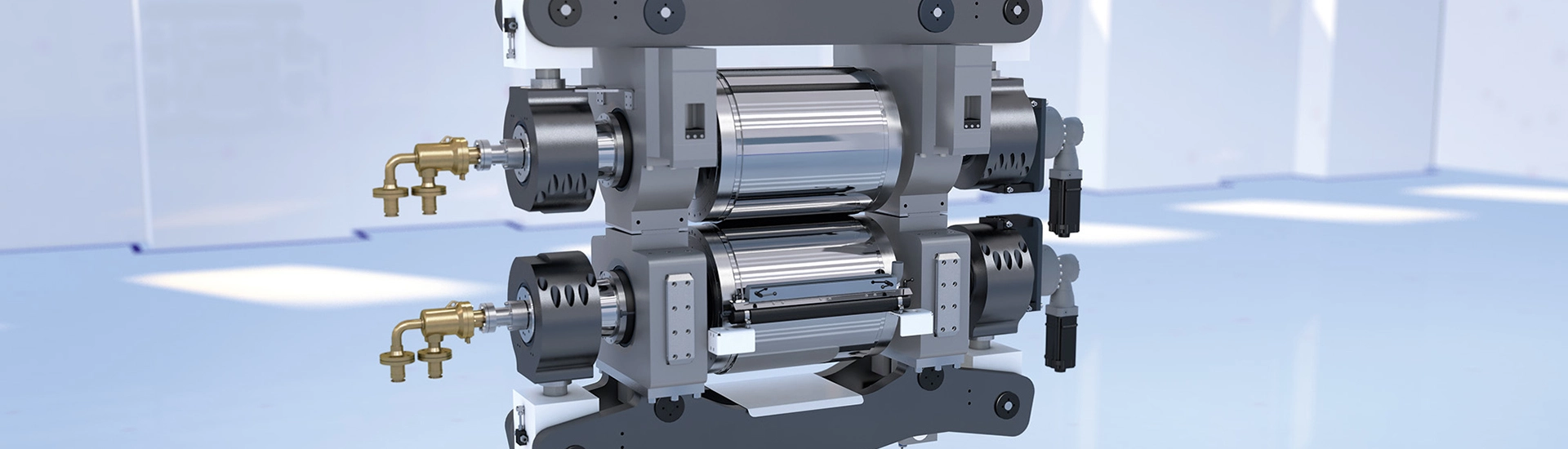

Das Herstellen einer Elektrodenfolie (Anode, Kathode) erfordert hohe und individuell einstellbare Linienlasten am Kalander sowie eine hochpräzise Kalibrierung. Die erforderlichen extrem niedrigen Toleranzen im Kalandrierprozess sind eine Herausforderung für die Maschine selbst.

Die jahrzehntelange Erfahrung von BREYER auf dem Gebiet der Glättmaschinenherstellung ermöglichte es, ein System zu entwickeln, das die hohen Anforderungen der Präzision in der Elektrodenherstellung erfüllt. Das präzise und zuverlässige Kalandersystem erlaubt extrem niedrige Dickentoleranzen.

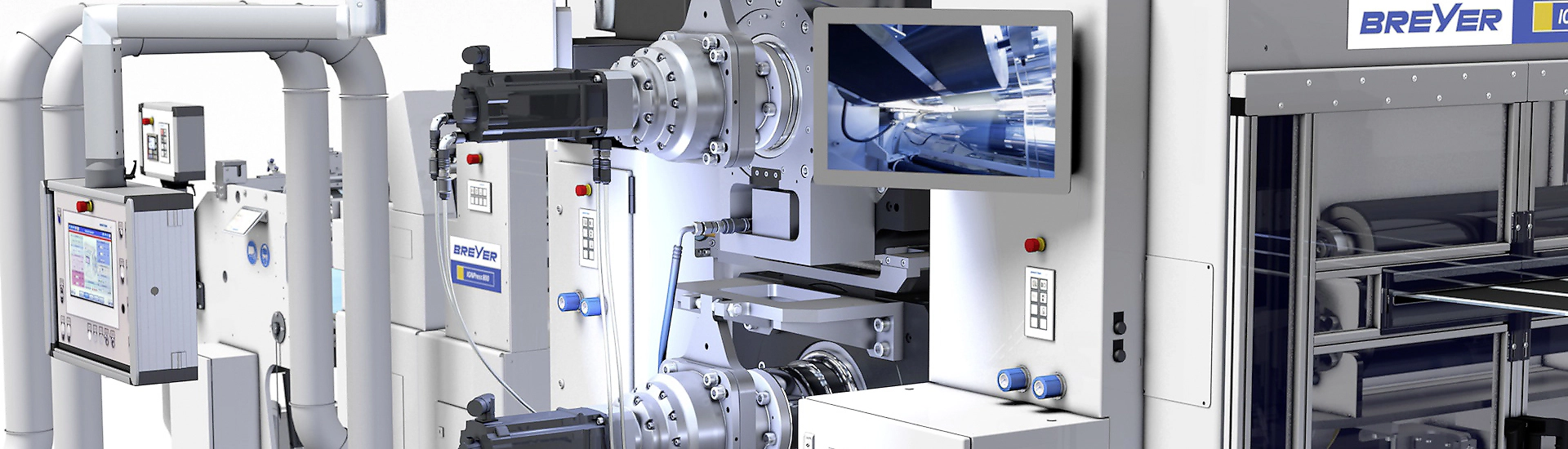

Für den Bediener ist entscheidend, die Foliendicke betriebssicher, schnell und reproduzierbar einstellen zu können. Mit der BREYER Spalteinstelltechnologie „fast & easy“ wird das Einstellen selbst in diesen kleinen Dimensionen fast ein Kinderspiel. Dieses System erlaubt in Verbindung mit der Inline-Dickenmessung den Aufbau einer automatischen Spaltregelung.

NEU: Closed-loop Dickenregelung mehr erfahren

VORTEILE

- Schnelle und reproduzierbare Dickeneinstellung

- Stufenlos einstellbare Linienlast bis zu 4000 N/mm

- Direkte Spaltmessung (closed loop)

- Hochpräzises Verdichten durch servohydraulische Spalteinstellung für Abstand und Kraft

- Geringste Dickentoleranzen

- Kraftvolle Einzelantriebe

- Sicherheitssystem

- Kompakte Bauweise

- Gegenbiegevorrichtung (Optional)

- Schneller Walzenwechsel (<3h)

- Komfortable Benutzeroberfläche, einfache Bedienung

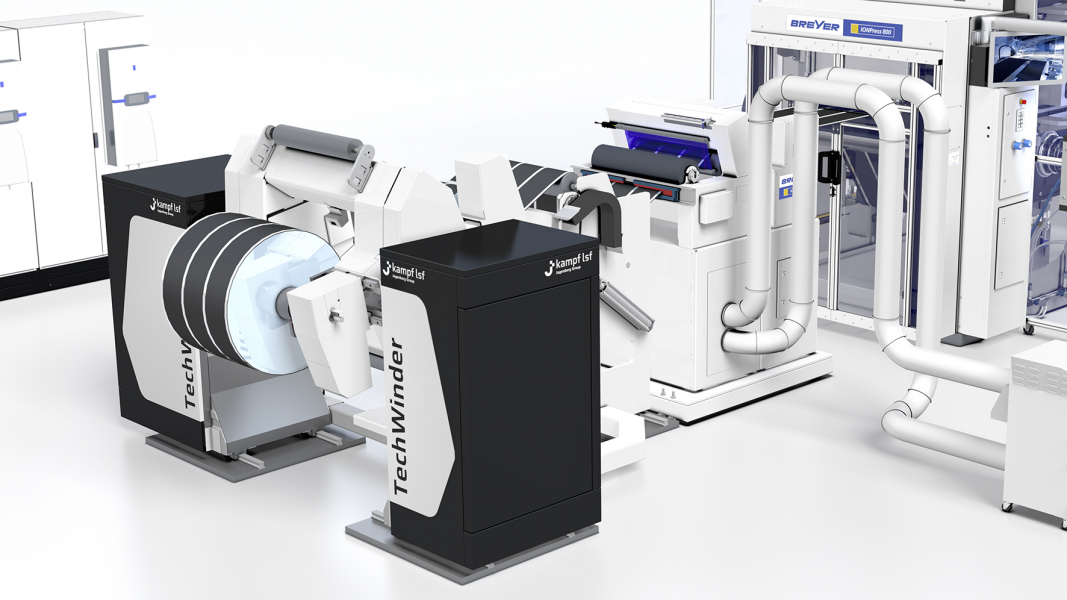

LIEFERUMFANG

- Abwickler für manuellen Coilwechsel bis 50 m/min, mit Zugregelung und Bahnkantensteuerung.

Automatische Wendewickler für hochautomatisierte Anlagen bis 100 m/min - berührungslose Bahnreinigung

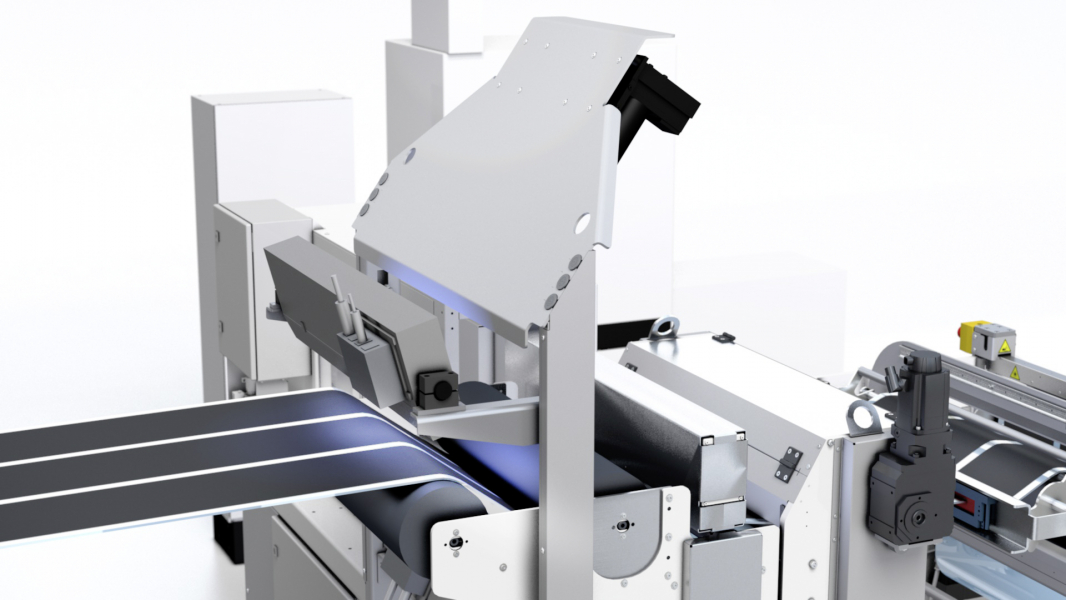

- Inspektionssysteme

- Kalander IONPress mit 400mm,600mm, 800mm oder 1400mm Walzenbreite.

- NEU: Kalander IONPress 400 core (Labor)

- Walzenschnellwechselsystem (<3h)

- Optionale Gegenbiegevorrichtung

- Walzenreinigung

- Effektive Substratvorwärmung

- Dickenmesssysteme

- Track&Trace

- Zugtrennung über geregelte Abzüge

- Aufwickler für manuellen Coilwechsel bis 50 m/min, mit Zugregelung und Bahnkantensteuerung.

Automatische Wendewickler für hochautomatisierte Anlagen bis 100 m/min - Gesamtsteuerung, Datenmonitoring

BREYER · Innovations for better Solutions

Nehmen Sie mit uns Kontakt auf und fragen Sie nach BREYER IONPress.

Die Zukunft hat begonnen - mit BREYER energy solutions werden Sie ebenfalls ganz vorne mit dabei sein.

Technische Daten

| Anlagengeschwindigkeit | 0,5 – 100 m/min |

| Walzentemperierung | Wasser / Thermalöl |

| Walzenbreiten | 400, 600, 800, 1400 mm |

| Walzen-Durchmesser | bis zu 800 mm |

| Walzen-Oberfläche | hartverchromt / Karbid |

| Walzenspalt-Einstellung | servo-hydraulisch gesteuert |

| Genauigkeit | ± 2 µm |

| Linienlasten | bis zu 4000 N/mm |

Anwendungsbereiche